This device, also known as the MAP sensor is located inside the ECU and is used to measure the absolute air pressure within the intake manifold. What is absolute manifold pressure you may ask ?

Absolute manifold pressure is the sum of ambient air pressure and boost pressure. For example, if the ambient pressure is exactly 1.0 bar and the turbo on your S2 is producing 0.8 bar of boost then the MAP value is 1.8 bar.

The MAP device within the ECU is a clever silicon chip that encases a pressure sensitive crystal which is subjected to manifold pressure by nature of a hose that runs through the bulkhead and onto the intake manifold. This hose is important to the healthy running of the S2, because if it is cracked or insecurely fitted erroneous MAP readings will result. The crystalline MAP sensor flexes under pressure and causes a change in the conductivity of its surrounding silicon components which provide a means for the ECU to calculate the absolute manifold pressure.

The MAP sensor in the standard 3B ECU has a dynamic range up to 2.0 bar. This is an important consideration for anyone considering an ECU chip upgrade on their S2 as the MAP sensor will need upgrading to a 2.5 or 3.0 bar device if large gains are sought after. Be advised that the ECU ROM and MAP chips are designed to work in collaboration with each other - you cannot mix and match them as they are calibrated differently.

Testing

the MAP

Using a digital multimeter (DMM) and an ECU break-out box (VAG1598) it is possible to test the MAP device if you have access to a reliable and controllable source of vacuum and pressure, such as a 'Mityvac' tool.

On the 3B ECU, the MAP output voltage appears at pin #31 - whilst on the ABY ECU you can find the MAP output voltage on pin #32. Monitor this pin whilst the MityVac is hooked up to the boost line on the ECU. The ECU needs to be connected to the engine loom and the ignition turned on for the tests.

If you don't have the breakout box, and few of us do :), you will need to open the ECU and access the middle pin of the MAP sensor to probe its output voltage under test.

If doing this with a MAP on the bench in isolation then you need to apply 5V across the outer two pins with the knowledge that the pin on the right (viewed from topside of the device) is the +ve leg.

At absolute vacuum (thats 0bar absolute pressure) you should read 0V at the MAP output.

At maximum rated pressure (absolute) on the MAP device you should see ~4.8V on its output pin.

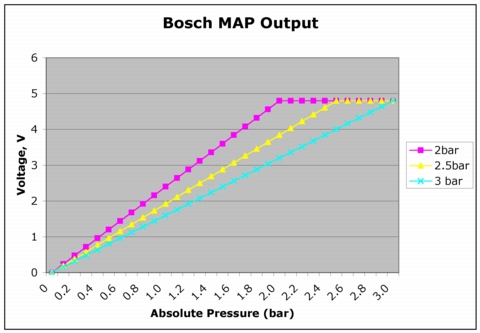

Every other pressure reading between those two extremes should lie on a straight line between the end points. The response of the MAP device is linear.

This means the 2bar (200kPa) MAP has a dyamic range of 2.4V per bar of absolute pressure, meaning that at a nominal ambient of 1bar absolute, you should see approx 2.4V.

The 2.5bar (250kPa) MAP on the ABY has a similar linear response but at a rate of 1.92V per bar absolute.

The 3bar MAP fitted to the RS2 (also made by Bosch but almost impossible to purchase anymore unless lucky on eBay) has the same linear characteristic but with 1.6V per bar.

The graph below shows the output voltages from a 2bar, 2.5bar and 3bar MAP device.

Note - Converting pressure measurement in pounds per square inch (PSI) to Metric Bar is quite simple when you know that 1 bar = 14.5 PSI